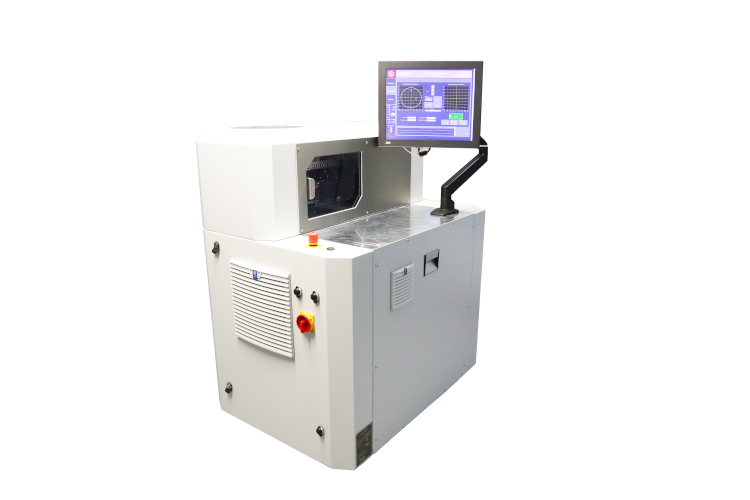

Der von uns entwickelte und vollautomatisierte Premium-Engraver zeichnet sich durch das bestehende und vollflexible Handhabungskonzept in Bezug auf Bandrichtung und Förderbandtechnologie aus. Die Premium-Gravur ist hierbei im Hinblick auf Brillengläser sowie Kontaktlinsen möglich. Die eingesetzte Technologie kann für Funktionsgravuren oder aber praktikable Branding-Gravur aller Art eingesetzt werden. Ein modularer Teileaustausch, eine internationale Ersatzteilverfügbarkeit sowie eine langfristige und stabile Prozessqualität sind weitere bemerkenswerte Qualitäten unseres LEnsMarkTec-Engravers. Unsere Maschine verfügt darüber hinaus über eine vollautomatisierte Prozesskontrolle am Objektiv und einem eingekapseltem Bewegungssystem, welches vor Verunreinigungen und Flüssigkeiten schützt. Im Lieferumfang enthalten ist eine Serverschnittstelle & Host-Kommunikation. Der Durchsatz, mithin die gravierten Teile, liegen bei 180 bis 210 Objektiven pro Stunde. Im Automatikmodus besteht die Option zur Erhöhung auf 300 bis 600 Objektive pro Stunde. Das Serviceintervall liegt bei ca. 4 mio. Linsengravuren.

Eximer-Laser-Gravur

Unsere Lasergravur-Technologie mit unseren speziell konzipierten Eximer-Lasern sind Gaslaser, die elektromagnetische Strahlung im ultravioletten Wellenlängenbereich erzeugen können. Sie sind zurzeit die flexibelsten und leistungsstärksten Quellen kohärenter Strahlung im ultravioletten Bereich des Spektrums. Die kurzwellige, ultraviolette Emission erlaubt eine nichtthermische Wechselwirkung mit zu bearbeitendem Material, so dass der Excimerlaser für Anwendungen, die eine hohe Präzisionsgenauigkeit und Dotqualität voraussetzen, am geeignetsten ist. Somit ist er für alle Materialien und Formen der Permanentgravur von Brillengläsern und Kontaktlinsen einsetzbar.